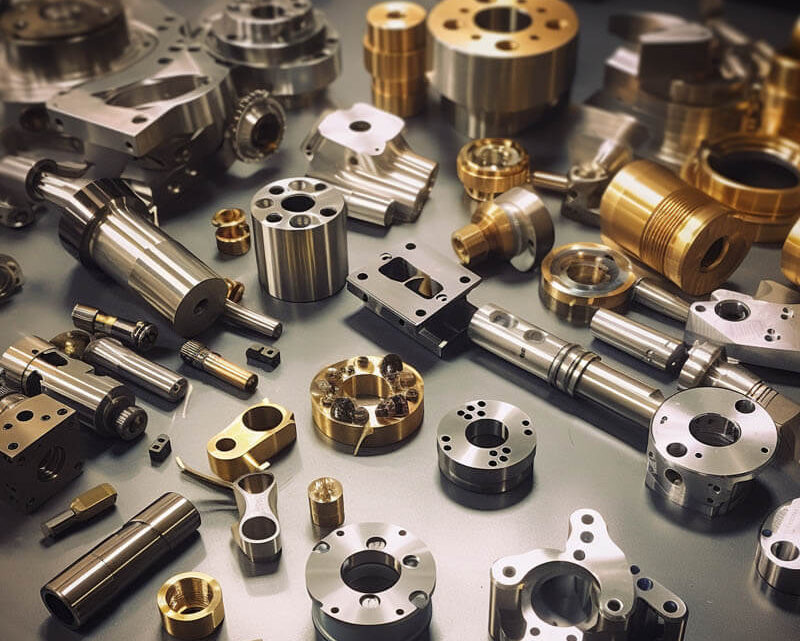

Small Batch CNC Machining Services from China

Precision, Speed, and Affordability: Experience Top-Quality Small Batch CNC Machining Services from China, Tailored to Your Unique Needs.

- Precision and Efficiency in Every Project

- Tailored Solutions for Custom and Low-Volume Production

- Wide Range of Materials and Capabilities

- Rapid Turnaround Times

- Cost-Effective Solutions for Small Quantities

Save 30% on average!

Why Our Small Batch And Prototype Manufacturing

Better Than Other Factories

Advanced CNC Technology and Automation

We install advanced CNC machines and computerized manufacturing systems that causes less reliance on man power then enhance production process. This technology also implies more accuracy and uniformity in production, which means less scrap and recall, making costs reduce also.

Efficient Production Management

For currently, Vertex has the distinction of the mass production and small-batch production management, as the small batch has many more programming and machine tuning tasks, higher professional requirements, only with accurate management, it can make the customer save more cost, and provide more stable product quality.

Strategic Location in ShenZhen China

Our company is located in Shenzhen, China and has a very complete CNC machining industry chain around the Pearl River Delta, so no matter how strict your needs are, we can meet them. Our 20 years of industry experience allows us to source high quality materials at lower prices and pass the savings on to our customers.

What Is Small Batch CNC Machining?

Small batch CNC machining refers to the use of computer numerical control (CNC) machines to produce small batches of customized parts. Small batch production is characterized by high accuracy, fast turnaround times, and cost-effectiveness. Compared to high-volume production, small-batch machining often better suits specific, lower-quantity needs and allows for easier design adjustments.

Different Types Of Small Batch CNC Machining

|

Type of Small Batch CNC Machining

|

Description

|

|---|---|

|

CNC Turning

|

Rotates the workpiece while a stationary cutting tool shapes it. Ideal for producing cylindrical parts like shafts and bolts with high precision, efficiency, and the ability to handle complex designs.

|

|

CNC Milling

|

Utilizes rotating cutting tools to remove material from a stationary workpiece. Suitable for creating intricate shapes, slots, holes, and flat surfaces with high accuracy, enhancing design flexibility and detail.

|

|

CNC Drilling

|

Uses rotating drill bits to create precise holes in the workpiece. Essential for parts that require exact hole sizes and placements, ensuring uniformity and consistency across small batch productions.

|

|

EDM Machining (Electrical Discharge Machining)

|

Shapes hard metals and intricate designs using electrical discharges. Perfect for components needing high accuracy and smooth finishes, especially in materials that are difficult to machine with traditional methods.

|

|

CNC Grinding

|

Employs abrasive wheels to achieve fine finishes and tight tolerances. Best for parts requiring high precision, smooth surfaces, and minimal surface roughness, often used for final finishing touches.

|

|

Multi-Axis Machining (3-axis, 4-axis, 5-axis)

|

3-axis: Moves the workpiece along X, Y, and Z axes for basic geometries. 4-axis: Adds rotation around one axis, increasing flexibility for more complex parts. 5-axis: Adds rotation around two axes, enabling the creation of intricate and detailed parts with complex geometries, offering maximum versatility.

|

Advantages Of Small Batches Machining

- Easily adapt to changing specifications and customer needs.

- Quick production cycles for fast delivery of parts.

- Tailored solutions for specific and unique customer requirements.

- Customers can test a wide range of different materials to verify the final results.

- Ideal for testing new products before full-scale production

- Suitable for various materials and complex part geometries.

Metal Material For Small Batch CNC Machining

|

Material

|

Description

|

|---|---|

|

Aluminum

|

Lightweight, corrosion-resistant, high strength-to-weight metal with excellent workability. Affordable grades like 6061 and 7075. Post-process options: sandblasted, anodized, powder-coated and so on. Suitable for various industries.

|

|

Brass

|

Brass is an alloy composed primarily of copper and zinc that possesses a distinctive golden yellow colour. It offers excellent workability, corrosion resistance and durability. Brass is widely used in applications such as Automotive, Electrical, Marine, Plumbing, Musical Instruments, Medical. Brass is also highly ductile and easily machined into a variety of shapes and sizes.

|

|

Copper

|

Highly conductive metal used in Electrical and Electronics, Telecommunications, HVAC, Energy, plumbing, and industrial machinery for its excellent thermal and electrical properties.

|

|

Titanium

|

Titanium is a strong, lightweight, corrosion-resistant metal with an excellent strength-to-weight ratio. Though more expensive and harder to work with, it's widely used in aerospace, medical implants, and sporting goods.

|

|

Bronze

|

Alloy of copper and tin, valued for its hardness and corrosion resistance, used in bearings, sculptures, and marine hardware

|

|

Magnesium

|

A lightweight metal with a high strength-to-weight ratio, magnesium requires careful processing due to flammable debris. Many camera and camcorder housings are made from magnesium alloy.

|

|

Steel

|

Alloy of iron and carbon, widely used in construction, automotive, and manufacturing for its strength, durability, and versatility.

|

|

Stainless Steel

|

Corrosion-resistant steel alloy used in kitchenware, medical devices, and construction for its strength, hygiene, and aesthetic appeal.

|

Plastic Material For Small Batch CNC Machining

|

Material

|

Description

|

|---|---|

|

POM (Polyoxymethylene)

|

Engineering thermoplastic known for high stiffness, low friction, and dimensional stability, used in precision parts like gears and bearings.

|

|

ABS (Acrylonitrile Butadiene Styrene)

|

Impact-resistant thermoplastic used in automotive parts, toys (e.g., LEGO), and consumer electronics for its toughness and versatility.

|

|

PC (Polycarbonate)

|

Strong, transparent thermoplastic used in eyewear lenses, safety equipment, and electronics for its impact resistance and optical clarity.

|

|

PEEK (Polyether Ether Ketone)

|

High-performance thermoplastic used in aerospace, medical implants, and industrial applications for its chemical resistance and mechanical properties.

|

|

PMMA (Acrylic)

|

Transparent plastic known for optical clarity, used in signs, lenses, and aquariums as a lightweight glass alternative.

|

|

PEI (Ultem)

|

High-performance thermoplastic used in aerospace, automotive, and electronics for its thermal stability, flame resistance, and high strength.

|

|

PAI (Polyamide-Imide)

|

High-strength, high-temperature resistant plastic used in aerospace, automotive, and industrial applications for its excellent mechanical properties.

|

|

HDPE (High-Density Polyethylene)

|

Versatile plastic used in bottles, piping, and plastic lumber for its strength, impact resistance, and chemical resistance.

|

|

PTFE (Teflon)

|

Non-stick, chemically resistant fluoropolymer used in cookware, gaskets, and electrical insulation for its low friction and high heat resistance.

|

|

Nylon (PA)

|

Durable, abrasion-resistant thermoplastic used in textiles, automotive parts, and industrial components for its toughness and flexibility.

|

We machine rapid prototypes and low & large volume production orders for customers in multiple industries: medical devices, aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, marine and robotics, and many more.

You will save 30-50% of the cost because of our efficient production capacity and cost control.

As an ISO 9001:2015 certificated manufacturing company, we offer SGS, RoHS, material certifications, and inspection report for our customers.

Our CNC milling services will support you from 1 pcs to 10k+ pcs, no matter prototype, low volume manufacture, or mass production.

Offering tolerances range from +/-0.001′′ to 0.005′′, depending on client specifications. We are experts in producing custom components.

Choose from 50+ engineering-grade plastics and metals, including ABS, polycarbonate, nylon, PEEK, aluminum, stainless steel, platinum, and copper for diverse part applications and industries.

Experience dependable and punctual delivery of your products from our CNC facility strategically located in Shenzhen, China, near major shipping ports for seamless transportation and peace of mind.

Small Batch CNC Machining

FAQs

How does small batch CNC machining differ from large-scale production?

Small batch CNC machining focuses on producing limited quantities, which allows for greater flexibility and customization. In contrast, large-scale production aims for high volumes, often requiring longer setup times and higher initial costs.

What is the typical lead time for small batch CNC machining projects?

Lead times can vary based on the complexity of the design, material availability, and production capacity. Generally, small batch projects can be completed within a few days to 2 weeks.

What precision tolerances can Vertex achieve?

Precision Machining Tolerances down to ±.0002″ (0.005mm).

Vertex can manufacture and inspect to tight tolerances per your drawing specifications.

Can small batch CNC machining accommodate design changes?

Yes, one of the key advantages is the ability to easily implement design changes between production runs. This flexibility is crucial for prototyping and refining designs before full-scale production.

What types of finishing options are available for small batch CNC machined parts?

Common finishing options include anodizing, plating, powder coating, painting, polishing, and sandblasting. These finishes can enhance the appearance, durability, and performance of the machined parts.